No Waste

No Waste

Can we really have no waste? This is a question that cannot be answered easily. There will always be some waste in our actions, our investments, our time, our purchases - no matter how hard we try, somewhere in the supply chain is likely to have waste elements.

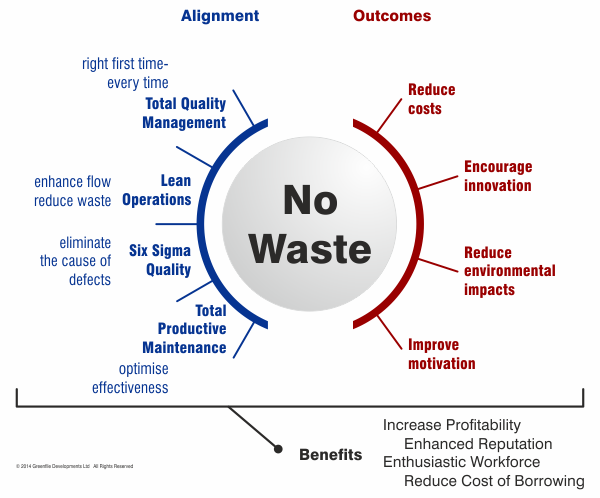

However, what we can do is to reduce these waste to a minimum level. The No Waste approach is a relentless pursuit to minimise waste in everything we do. Whilst some may see this as obsessive, just look at the range of possible outcomes and you can quickly see why we want our clients to focus on this.

Reducing wastes will:

- Reduce costs;

- Encourage Innovations;

- Improve motivation in the workforce; and

- Reduce environmental impacts

And these all contribute to increased profitability, enhanced reputation and an enthusiastic workforce. The ability to reduce waste may even contribute to a reduced cost of borrowing as your organisation's enhanced effectiveness will certainly reassure lenders.

So what sort of waste are we talking about? The seven wastes that Toyota outlined? The waste in talent and ideas?

Yes to all of these and also to the wastes caused by poor systems, poor governance, badly defined procedures, workarounds and improvisations. Waste is an drain on your business - investment, morale and reputation.

So what sort of waste are we talking about? The seven wastes that Toyota outlined? The waste in talent and ideas?

Yes to all of these and also to the wastes caused by poor systems, poor governance, badly defined procedures, workarounds and improvisations. Waste is an drain on your business - investment, morale and reputation.

In fact waste is an anti-sustainability. Something that is entirely opposite to what sustainability is all about: waste costs money, damages motivation and team spirit and causes unnecessary impacts to the environment.

Our approach to no waste is aligned to world -class practices such as Total Quality management, Lean operations, Six Sigma Quality and Total Productive Maintenance - techniques that have a long history of cutting waste. We have added to this by coupling the waste reduction to innovation, workforce development as well as

effective policy and governance.

Find out more about our waste reduction approach at the NoWaste® website (this link opens in a new window).

top